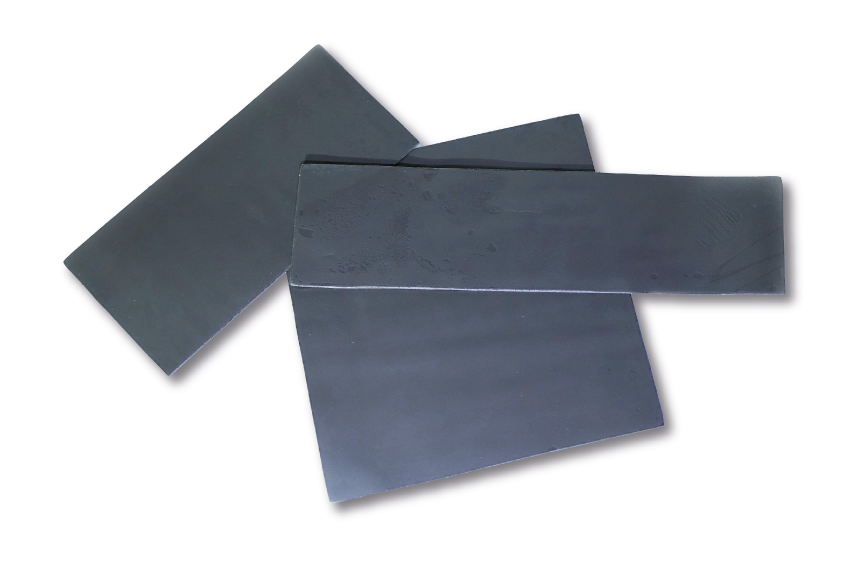

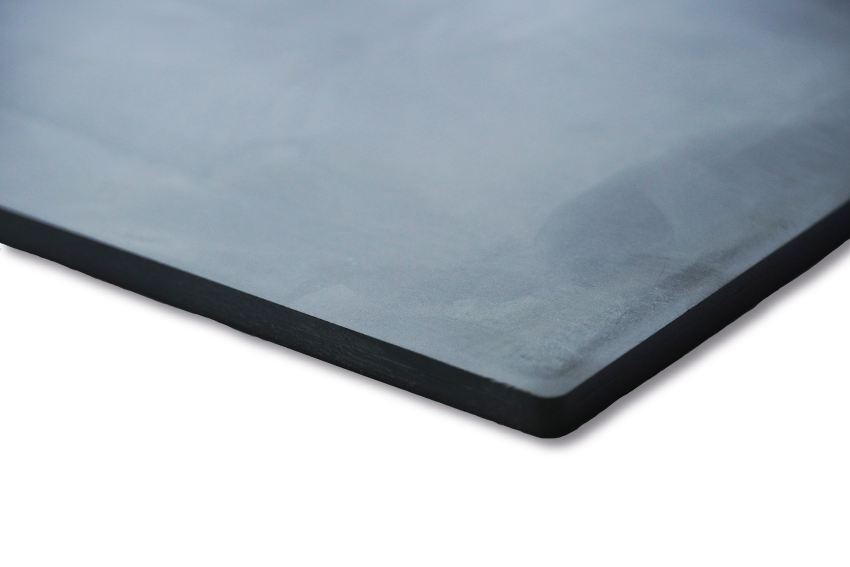

Softzorb - Optimal absorber and Gap Filler for 18-35 GHz applications

Softzorb is a softer variant within our supplier Laird’s EccoSorb product line, developed to meet the need for high-performance absorber materials. The unique feature of Softzorb is its low deflection force, making it ideal for filling cavities and protecting sensitive components in electronic equipment.

Benefits of Softzorb as an absorber and Gap Filler:

- Effective EMI-absorption (18-35 GHz): Softzorb delivers excellent performance by minimizing leakage around the absorber, thereby optimizing electromagnetic shielding.

- Soft and flexible design: The material is designed to avoid damage to other components by compressing easily without causing stress.

- Gap filling and tolerance balancing: Perfect for balancing stack-up tolerances in tight spaces or as an interface material between surfaces.

Why Softzorb?

Softzorb is ideal for use in electronic devices and other systems where there is a need to:

- Reduce electromagnetic interference (EMI).

- Protect sensitive components from physical stress.

- Improve performance by sealing cavities and eliminating leakage.

The soft nature of Softzorb makes it easy to apply in complex environments, including situations where lids may come into contact with the material. With its high compression capability, it maximizes absorption properties and ensures long-lasting reliability.

RF FOAM - Flexible and Structural Microwave Absorbing Foam

Lairds microwave absorbing foam is an innovative solution that combines lightweight design with excellent broadband absorption. The product is customizable and can be manufactured in customer-specific shapes and sizes, making it ideal for a wide range of applications.

Features and benefits:

- Lightweight construction: Perfect for reducing weight in sensitive systems without compromising performance.

- 3D formability: Can be molded, machined, or bonded into complex structures and components.

- Outdoor option: For outdoor applications, the material can be filled with a closed-cell rigid polyurethane foam to create a structural broadband foam.

- High-performance absorption: Ideal for enhancing antenna patterns, radomes, and other applications in enclosed or exposed environments.

Applications

- Satellites

- Radomes

- Antenna pattern improvement

- Aerospace and defense industries

When skins are applied to the foam, it can be transformed into rigid yet lightweight structural panels, making it a versatile solution for advanced industrial applications.

Why Microwave Absorbing Foam?

Laird’s products offer industry-leading performance and are designed to meet the demands of the aerospace, defense, and other high-tech industries. Its adaptability and advanced material technology make it ideal for managing electromagnetic interference (EMI) and optimizing system functionality.

Ruggedized specialty Microwave and Custom Magnetic Absorbers - Designed for military and aerospace applications

Lairds rugged microwave absorbers and custom magnetic absorbers are engineered to meet the strict demands of the military and aerospace sectors. These absorbers deliver reliable performance for free space reflectivity reduction, cavity resonance suppression, and tuned functionality, even in extreme environments across land, air, and sea

Why choose Rugged Absorbers?

- Military and Aerospace standards: Compliant with military and aerospace requirements, ensuring reliability in critical applications.

- Extreme environmental durability: Designed to perform flawlessly in challenging conditions, including extreme temperatures and vibrations.

- Versatile solutions: Ideal for managing electromagnetic interference (EMI) and enhancing sensitive electronics.

Applications:

- Free space reflectivity: Reduce electromagnetic interference in open environments.

- Cavity resonance: Effectively suppress resonances to improve system performance.

- Military/aerospace technology: Tailored solutions for high-sensitivity applications.

Structural Absorbers - Customizable solutions for attenuation and EMI management

Lairds structural absorbers are designed to address unique design challenges where pre-cut materials are insufficient. Our comprehensive range includes epoxy, silicone-based, and thermoplastic absorbers that can be molded, cast, or machined to meet complex geometric requirements.

Features and benefits:

- Temperature-resistant: Withstands temperature cycling and is reflow-compliant.

- Durable: Weatherproof with excellent abrasion resistance for long-lasting performance.

- Low outgassing: Suitable for space applications and sensitive environments.

- Customizable: Precision-machined, injection-molded, or cast solutions for both low and high-volume production.

- Magnetically loaded: Suppresses surface currents while remaining non-conductive, allowing direct contact with circuitry.

Applications and product options:

- Injection Molded Absorbers: Explore ECCOSORB MF PA, a high-temperature absorber made from magnetically loaded thermoplastic polyamide.

- Machinable stock: ECCOSORB® MF500F is widely used as a waveguide absorber and in attenuators and coaxial lines.

- Castable Absorber Compounds: ECCOSORB CR offers multiple resin options to suit various applications.

For more information about our absorbers, contact us!